GO3 - Syn Interconnection

Grid

Operation

Part 3

System

Interconnection

Synchronous

Performance of grid system was

encouraging. Found to be favorable for its stiffness with increased system bias

and inertia. Interconnection with neighboring system is beneficial to both the

systems. It facilitates power assistance to each other during distress condition.

Also Government of India undertaking like NPC, NTPC, NHPC had established

pooled power plants in the region. Interconnection

were also necessary to draw share of power from such plants. So

interconnections with neighboring systems were established. But with this

operation criteria had changed.

Review of water supply system will high light the issue.

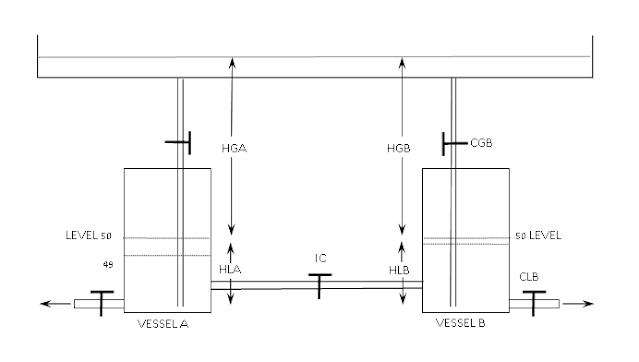

Water supply system setup is modified accordingly. There are two tanks with its inflow and outflow lines as in the figure. Both the tanks are connected at bottom by a pipe line.

Initially interconnecting line

valve IC is kept closed. In this condition both the systems are independent and

behave like standalone system as discussed earlier. Water level in tank A is

exclusively regulated by control valve CGA and CLA and it has is no influence

on water level in tank B and vice a versa.

Initially inflow through control

valves CGA and outflow through control valves CLA are adjusted that water level

in tank A is maintained 50%. Similarly control valve CGB and CLB are also adjusted

that water level in tank B is also maintained at 50%.

Now opening of valve IC on interconnecting

line has no effect on water level in any tank.

Now there is passage for water to flow in either direction but there is

no water flow in any direction because of equal level in both the tanks.

Make some change in tank A

only. Control valve CLA is opened to increase outflow. As usual, water level in

A drops because outflow is more than inflow.

Consequently, head HGA will increase

and inflow through CGA increases. Also head HLA will decrease and outflow through

CLA decreases.

But water level in B is same as

before. So water flows from high level in B to low level in A. Now level in B

also drops. Consequently, head HGB will increase and inflow through CGB increases.

Head HLB will decrease and outflow through CLB decreases.

Tank B inflow has increased and

outflow has decreased. Means there is surplus inflow that will flow to A to

makeup the shortage.

This will continue till total

inflow matches total outflow. In this case level drop is less than independent

working.

In other case increase of

inflow in tank A causes rise of level. So inflow will decrease with decrease of

HGA. Outflow increase with increase of HLA. Water will flow from tank A with

higher level to tank B at lower level. So level in B also increase. Inflow in B

will decrease and outflow increase. Ultimately stabilize at little higher

level.

Similarly level stabilize with

auto control when increase/decrease of inflow/outflow in any tank.

Three observations

- Disturbance in one tank reflected in other tank.

- Equal level is maintained in both tanks with simultaneous rise/drop.

- Water flow from one tank to other.

1. Grid system also operates in similar manner.

Consider two power systems A

and B having interconnection as shown in the figure

Both

the systems are running independently with ideal operating condition having

balanced load and generation at normal frequency of 50 Hz. There would not be

any power flow when these systems are connected through tie line.

Let load X MW increased in system A after interconnected. System frequency will drop due to shortage of total generation against total demand. Drop in frequency is common in both the systems as they are interconnected. Generation in system A as well as in system B will increase by governor action due to drop in frequency. Similarly power demand by loads in system A as well in system B will reduce with drop in frequency due to frequency dependant loads. Consequently system B will have surplus generation. So power flow from system B to system A through tie line. Shortage of generation occurred in system A due to rise of load is partially met by gain in own system and balance by power import from system B. Whole grid will stabilize at little lower frequency. Of course drop of frequency will be smaller compared to standalone system because of auto corrective action from both the system.

System

frequency will rise during loss of load in system A. Generation in system A as

well as in B will reduced by governor action due to rise in frequency.

Similarly power demand by loads in system A as well in system B will increase with

rise in frequency due to frequency dependant loads. Power will flow from system

A to B and grid will stabilize at little higher frequency.

Similarly

frequency is controlled during add/drop of demand/generation in any system.

Three

effects during mismatch in any system.

- Effect of mismatch in one system is experience by other system also.

- Rise/drop of frequency is throughout the grid.

- Extra power flow between the systems.

1. Consider systems A and B were operating with following data

System

A has 15000MW Demand, 15000MW Generation and 600MW Bias

System

B has 10000MW Demand, 10000MW Generation and 400MW Bias

System

is operating at 49.90 Hz

Only

system A has 300 MW loss of generation.

Combined

bias = 600 + 400 = 1000 MW

Drop

of frequency 300/1000 = 00.30 Hz

Gain

in system A = 00.30 × 600 = 180 MW

Gain

in system B = 00.30 × 400 = 120 MW

This

is surplus in system B and will flow to system A

System

A had shortage of 300 MW

Gain

in system A itself is 180 MW

Net

shortage = 300 – 180 = 120 MW

This

is received from system B

So

both systems are stable at 49.90 – 00.30 = 49.60 Hz

Only

system frequency has to be monitored and controlled in standalone system.

Governor was actively regulating generation to maintain frequency within limit.

But two parameters have to be monitored and controlled in case of interconnected

grid system.

Variation

of demand or generation in one or both the system has following effect.

- Frequency variation. > Depends on overall surplus/deficit of generation.

- Tie line flow variation. > Depends on defaulting system.

1. Control centers for this purpose were established. These are known as Load Dispatch Centers. Along with above two primary functions, center has other responsibility of economic power dispatch, system security and others. So center was authorized to instruct the power stations and load centers to operate as required for power system operation with above objectives. The center has direct communication with all power stations and load centers and with such center in other power systems.

Following thumb rule was useful for corrective action.

|

Sr. |

Frequency |

Tie-line

Flow |

Default

system |

|

1 |

High |

Import |

Other

System |

|

2 |

High |

Export |

Own System |

|

3 |

Low |

Import |

Own System |

|

4 |

Low |

Export |

Other

System |

Of course this is not perfect criterion but generally works well.

In

case of 1 and 4, other system LDC is contacted for corrective actions.

In case of 2

1.

Release load if any restriction on any type of load.

2.

Reduce generation. > costly

first.

In case of 3

1.

Pick up generation. >

costly last.

2.

Restrict load as per

decided priority.

This

was working well during normal load variations and small disturbances. But it

is emergency during sudden loss of generation due to tripping of generator or

loss of load due to tripping of trunk line to big area. System condition may be

severe due to critical frequency and/or critical tie line flow and/or critical loading

on network (line/s or transformer/s) in any system. So concern system operators

have to act quickly to reinstate normal stable condition at the earliest. Manual

control has its own limitations. Automatic control system is the solution.

Load Frequency Controller (LFC)

LFC

is the device that calculates Area Control Error.

Area Control Error ACE = ΔPi + BΔF

Where

Pi = Power Import

deviation = Pa - Ps

B = System Bias = Power/Hz

Fd = Frequency deviation

= Fs – Fa

Pa = Actual Power Import

Ps = Schedule Power Import

Fs = Schedule

Frequency

Fa = Actual

Frequency

Figure of ACE indicates severity of default condition.

Positive ACE indicate

generation short of demand.

Negatives ACE indicate over generation

than demand.

All tie line flow and frequency

data is fed directly on line to the controller. Also system bias, schedule

frequency and schedule tie line power are set manually. Application of LFC may

be as operators guide. Or it can have online remote control to regulate generation

of assigned power plants.

Effectiveness of such control

depends on installation of such device by all the systems in the grid. Some

state had installed such control but was not successful due to followings.

·

This was not installed

by any other system in the group.

·

There was frequent

up/down of generation. Such variations were detrimental to thermal generator

sets. Thermal generating sets have limited range for on line regulation.

Interconnected

systems can be operated in one of the three modes with mutual consents.

Flat Frequency Control.

Control

of frequency is primary task.

Suitable

for alike systems where in both systems act to corrects frequency.

Suitable

for small system connected to large system. Large system controls frequency

whereas small system adjusts tie line flow.

Tie Line Bias Frequency Control.

Tie

line flow is regulated in accordance with frequency. Area control error will be

zero provided system bias setting is correct.

Grid

system has advantage of stiffness. Interconnected systems are stable against

any eventuality in any system in the group. Larger the group better is the

performance. So many systems were interconnected to form large group up to

regional level. Regional grid has multiple interconnections with different

systems. There may be more than one tie line between any pair of system. It is

also possible that particular pair of systems may not have any direct tie line

but they are interconnected through other systems. There is pooled

generations in different systems.

Tie

line flow in two systems was bilateral. Export of one system is import for

other system. But it is different in grid system. Each system has to derive tie

line flow on net transfer base as under.

Schedule

for power draw is algebraic sum of its share from various ISGS in the grid plus

any bilateral agreement for import or export from/to other source.

Actual

power drawn is algebraic sum of power import/export on all tie lines plus injection

by ISGS within the system.

Meanwhile regional load

dispatch center were functional helping in interstate coordination. System control

continued to be manual and there was wide variation in frequency and tie line

flows. Generation on all units drops including cheap sources by governor action

whenever frequency increases. Import from grid increase and had to pay for it

at higher rate. Frequency rise were from very low to better level due to load

shedding by one or other constituent. Similarly frequency drop with resumption

of such loads and costly generation was picked up due to governor. Thermal

stations were subjected to continuous load up down with frequency and each time

readjustment manually. Such operation had adverse effect on power plants. This

is when no ABT. This needed to get rid of the nuisance.

Solution was as in our water supply system as under.

The inflow pipes which were up to bottom of the tank under the water were cut short as shown. Now pipes were out of the water and free of back pressure related to water level in the tank. Hence there is no effect on inflow due to change in level in the tank.

Generator governor control set

for full load with no droop so that generation has no effect of change in frequency.

Ultimately frequency control is as shown in the chart hereunder.